Safe Use of Lifts, Lifting Equipment & Associated Equipment (LOLER)

Overview Of Management & Colleague Responsibilities

Manager Responsibilities

Below is an overview of the responsibilities which is intended to support managers in identifying their key duties that need to be taken to comply with the requirements of this document and the safety management systems of the National Ice Centre.

- Managers need to ensure that all lifting equipment provided is suitable for the intended use.

- Managers are required to ensure that suitable and sufficient risk assessments have been carried out for the use of lifting equipment.

- Managers must ensure that all lifting operations are planned, supervised and undertaken by a competent person.

- Managers must understand when an additional lookout person is required for an activity and that they are provided.

- Managers must ensure that the lifting equipment is of sufficient strength and stability.

- Managers are required to ensure that all lifting equipment that is designed to carry people is it fitted with a suitably guarded carrier and a method of rescue in place.

- Managers need to ensure that all required warning signs and markings are displayed.

- Managers need to ensure that all colleagues who use lifting equipment has received adequate information, instruction, training and supervision.

- Managers need to be aware of the arrangements that are in place for regular inspection for the lifting equipment and that those inspections records are retained.

Employee Responsibilities

The Health & Safety at Work Act 1974 section 7 requires all employees to consider their own health & safety and the safety of others.

As an employee of the National Ice Centre, if you have concerns in relation to health & safety that is likely to cause you or someone else, injury or ill health then you must ensure that the concern is communicated to your manager immediately.

You are also required to co-operate with the management of the National Ice Centre to ensure compliance with the health & safety arrangements, policies and procedures and work to the requirements identified within this document.

Introduction

Date: October 2023

Issue: No. 4

Subject: Safe Use of Lifts, Lifting Equipment & Associated Equipment (LOLER)

This document forms part of the National Ice Centre’s organisational written safety policy arrangements.

Departments, services or teams may consider it appropriate to develop additional guidance and systems of work on specific work related activities.

Where proposals, additional guidance or changes to systems of work will have an impact on health, safety and welfare, this will be discussed and agreed at the Health & Safety Committee.

If you have any questions or require further information or support on the contents of this document, please contact the NIC Health & Safety Advisor or Corporate Safety Advice.

Legal Requirements On The Management Of Any Lifting Equipment

The Health & Safety at Work etc. Act 1974 places general duties on employers to ensure the health, safety and welfare of their employees at work and anyone else who may be affected.

This general duty extends to include the risks from any lifts, lifting equipment, hoists or equipment used within any lifting process.

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) places specific duties on employers to ensure that all equipment is safe and is maintained.

LOLER considers the definition for lifting equipment and the types of equipment or activity which may include cranes, lift trucks, goods / passenger lifts, inspection hoists, ropes, bell hoists and vehicle tail lifts, person hoists and bath lifts.

The legislation also extends to not just the mechanical aspects of the lifting equipment but also attachments and accessories such as eyebolts, chains and slings and any other equipment that is used as part of the lifting process.

Definition Of Strength, Suitability & Stability

Managers need to be aware that a competent person (e.g. installer / manufacturer) needs to ensure that lifting equipment has adequate strength and capability, particularly mounting and fixing points.

This check includes considering the strength of the ground where the equipment is to be positioned for use.

Other checks may include the pressure within Pneumatic tyres which must be correctly inflated and checked on a regular basis.

Loads are not normally lifted by straps or banding unless they have been designed for the purpose and a clear and approved method statement is in place.

Please note, in this instance, competence to identify a suitable method will require specific technical knowledge, and competence cannot be attributed to any person without this technical knowledge.

Requirements For Equipment Designed For Lifting Persons

Managers must ensure that all lifting machinery is fitted with a suitably designed carrier, which includes edge protection, working platform and overhead protection where appropriate.

Managers must ensure that all lifting machinery is fitted with a suitably designed carrier, which includes edge protection, working platform and overhead protection where appropriate.

Colleagues must never be lifted on the fork arms or, pallets balanced on the fork arms of a lift truck as there is an obvious risk of falls.

In the event of failure of any equipment designed for the lifting of persons, Managers need to have considered a suitable method of rescue.

Where a significant risk of overturning or overload is present, the equipment used must be provided with devices to provide a clear audible or visual warning as lifting limits are being approached.

Marking Of All Lifting Equipment

Managers must ensure that all lifting equipment, including accessories e.g. slings, clamps etc, is clearly marked and indicates the safe working load and the maximum people to be carried.

Managers must ensure that all lifting equipment, including accessories e.g. slings, clamps etc, is clearly marked and indicates the safe working load and the maximum people to be carried.

Equipment must not be used for lifting people where if it is not designed or identified for that purpose.

Positioning Of Lifting Equipment & Organisation Of The Lifting Operation

Managers need to ensure that lifting equipment is positioned / installed so that it minimises the need to lift loads over people, preventing the potential risks of falls causing injuries.

Equipment should only be used when there is sufficient headroom and appropriate measures in place to prevent overturning.

All lifting operations need to be planned, supervised and carried out by a competent person.

If the operator of lifting equipment is unable to see the full path of the load, there must be a system of work to ensure that the load is prevented from colliding with, for example, a ‘signal’ or an additional lookout person.

Examination & Inspection Regimes

Managers need to be assured that all lifting equipment and accessories under their control has been thoroughly examined by a competent person prior to user following initial installation.

Managers must also be satisfied that their lifting equipment and accessories has been thoroughly examined by a competent person (e.g. an Insurance engineer surveyor) in accordance with an examination scheme.

Any examination should take into account the condition of the lifting equipment, the environment in which it is used and the number of lifting operations and loads lifted.

For a person lift, the intervals should be at least every 6 months, any other lifting equipment at least every 12 months i.e. a lift truck.

Reports of thorough examinations and other documents such as the current record of inspection should be kept and readily available on site.

Managers must ensure that all reports of thorough examinations and other documents such as the current record of inspection is kept on site and is readily available.

Managers must ensure that there is a system in place to ensure that all defects identified during use, such as cracks in a lift truck chain, or damage to textile slings are reported to the manager with responsibility for this equipment as soon as possible.

Managers must ensure that there is a system in place to ensure that all defects identified during use, such as cracks in a lift truck chain, or damage to textile slings are reported to the manager with responsibility for this equipment as soon as possible.

Where the risk assessment identifies a significant risk in the use of lifting equipment, additional controls should be implemented.

Visual Inspection Of Associated Equipment Prior To Use

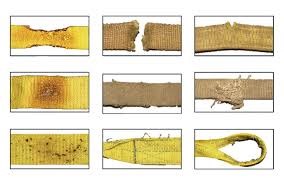

Managers need to ensure that a system is in place for the visual inspection for faults and damage to all equipment associated with a lifting process, such as shackles, chains, ropes and slings etc prior to use e.g. rips in hoist fabric, badly worn / damaged chain etc.

Where a fault is identified, that equipment must not be used and new / replacement equipment must be provided before any lifting operation commences.

The Inspection regimes for this associated equipment may not form part of the formal arrangements organised by corporate property and therefore managers need to consider local arrangements.

Young Persons

Although not explicitly identified within the legislation, young persons i.e. those under 18 years of age must not use high risk lifting equipment, unless they have sufficient training, maturity and competence, or they are undergoing training with adequate supervision.