Electricity at Work including the Maintenance of Portable Electrical Equipment

Overview Of Management & Colleague Responsibilities

Manager Responsibilities

Below is an overview of the responsibilities which is intended to support managers in identifying their key duties that need to be taken to comply with the requirements of this document and the safety management systems of the National Ice Centre.

- Each manager will need to ensure that there is an asset register, detailing all portable equipment that their colleagues use.

- Managers must ensure that all appliances that require testing and those that do not are identified.

- Managers need to consider as part of the PATs process, an appropriate testing interval for the equipment. This consideration must be formalised.

- Managers need to be satisfied that all colleagues are staff are aware of pat requirements and their requirement to visually check equipment prior to use and not to use any equipment with a visible defect.

- Managers are required to have a process which ensures all equipment that does not pass the PATs testing, or has a identified fault or defect is taken out of service for repair or disposal.

- Managers must ensure that no block adaptors are used for electrical equipment within NIC owned premises.

- Managers need to ensure that no modification occurs to any electrical equipment or electrical supply within the working environment unless undertaken by a formally qualified and competent person.

- Managers must ensure that no work is done on a live electrically supply except under Permit to Work buy a formally qualified and competent person.

Employee Responsibilities

The Health & Safety at Work Act 1974 section 7 requires all employees to consider their own health & safety and the safety of others.

As an employee of the National Ice Centre, if you have concerns in relation to health & safety that is likely to cause you or someone else, injury or ill health then you must ensure that the concern is communicated to your manager immediately.

You are also required to co-operate with the management of the National Ice Centre to ensure compliance with the health & safety arrangements, policies and procedures and work to the requirements identified within this document.

Introduction

Date: October 2023

Issue: No. 4

Subject: Electricity at Work including the Maintenance of Portable Electrical Equipment

This document forms part of the National Ice Centre’s organisational written safety policy arrangements.

Departments, services or teams may consider it appropriate to develop additional guidance and systems of work on specific work related activities.

Where proposals, additional guidance or changes to systems of work will have an impact on health, safety and welfare, this will be discussed and agreed at the Health & Safety Committee.

If you have any questions or require further information or support on the contents of this document, please contact the NIC Health & Safety Advisor or Corporate Safety Advice.

Legislative Requirements

Managers should appreciate that the combination of the Health and Safety at Work Etc. Act 1974, the Provision and Use of Work Equipment Regulations 1998 and the Electricity at Work Regulations 1989 apply to all electrical equipment used in, or associated with, places of work.

The scope of this legislation extends from distribution systems down to the smallest piece of electrical equipment.

It is clear that there is a requirement to inspect and test all types of electrical equipment in all work situations.

Electricity At Work Regulations 1989

The Electricity at Work Regulations 1989 provides information on how to work safely on or around both electrical equipment and supply.

This legislation also requires that all electrical systems are safe and not going to put any person into a position of danger.

This legislation also identifies that any maintenance on or around electrical systems must also be done in such a way as to prevent danger.

Strength and capability of electrical equipment

Strength and capability of electrical equipment

No electrical equipment shall be put into use where its limits may be exceeded in such a way, as may give rise to danger.

Adverse or hazardous environments

Any equipment to be used in harsh environments which may give rise to damage e.g. dust, water, excessive temperature, must be designed and constructed to prevent damage from those hazards.

Insulation, protection and placing of conductors

All electrical conductors such as wiring must be covered with a suitable insulating material that is in good condition.

Earthing or other suitable precautions

All electrical systems and equipment must be effectively earthed or where this is not the case, other controls must be provided that ensure that the danger is avoided.

Integrity of referenced conductors

When using any equipment or electrical system which relies on the earthing of the electrical supply such as Residual Current Devices (R.C.D.), no alterations to that supply or the equipment must be undertaken that will impede the effectiveness in preventing danger.

Connections

To prevent danger, every electrical joint and connection within the system shall be mechanically and electrically suitable for use.

Means for cutting off the supply and for isolation

Means for cutting off the supply and for isolation

A suitable means for disconnecting both the supply and equipment must be identified as to prevent danger.

This is particularly important when maintenance and repair of either the supply or equipment is required

Precautions for work on equipment made dead

A system to ensure that once the electrical supply or equipment has been isolated, a method to ensure that it is not reconnected must be implemented

Work on or near live conductors

Managers must ensure that live working is only be allowed if:

- It is unreasonable for the relevant conductors to be dead

- Suitable precautions have been taken to prevent danger

- A permit to work procedure is in place

In all circumstances where live working is to take place, this must be supported by a permit to work and the person undertaking the work must be a suitably qualified and competent electrician.

Persons to be competent to prevent danger and injury

No person shall be engaged in any work activity where technical knowledge or experience is necessary to prevent danger or, where appropriate, injury, unless they possess such knowledge or experience, or is under such degree of supervision as may be appropriate having regard to the nature of the work.

Fixed Wiring & Installations

Managers must ensure that all modifications, renewal or inspections of existing fixed wiring and installations is undertaken by competent and qualified electrician only.

This work is often included as part of a schedule of works and is managed and organised through Facilities Management .

Work on Fixed Electrical Plant and Equipment

All pieces of single or multiphase equipment permanently wired into the electrical distribution system should, as far as it is reasonably practicable, be maintained to prevent danger.

Managers must be assured that such maintenance and any necessary repairs is only done by a competent contractor or competent colleague and the frequency of maintenance should be determined in the light of the manufacturer’s recommendations and the type of use.

- Equipment of this type should be installed in such a way that the means of access, working space and lighting are adequate to prevent danger to persons working on or near the equipment;

- Isolators must be readily accessible and steps taken to prevent the equipment from inadvertently being made live whilst it is worked on.

Portable Electrical Equipment Classes

The British Standard (BS) and International Electro-technical Commission (IEC) define appliances into two categories Class 1 and Class 2.

Class 1

Appliances that have a functional insulation throughout and an earth-connected case (earthed appliances).

There is no agreed symbol in use to indicate that equipment is Class 1.

Class 2

Class 2

Appliances that have a functional and additional insulation.

In these appliances metal parts cannot become “live” under any fault conditions (i.e. the appliances are double insulated with no earth connection).

Such appliances have the double square symbol:

Portable Electrical Equipment Management

Managers must ensure that appropriate systems are in place to maintain electrical safety within their premises.

The duties for organising and the visual checking of new and existing equipment can be delegated to other staff members.

It is important to recognise that when delegating this duty, the manager must ensure the person they have charged with the task is able and competent to undertake the duty required.

New equipment (purchased)

New portable electrical equipment should be visually inspected prior to use.

However formal testing by a competent person does not need to be specifically arranged before use but it must be put onto the register and included on the next scheduled test.

In addition to this, proof of purchase must be retained and kept with the electrical register until it has been formally tested.

Other electrical appliances

Safety testing by a competent person must take place for all electrical appliances that are introduced within the workplace that were not purchased brand new.

Any equipment introduced for personal use that was not purchased by NIC is subject to the same inspection / testing regime.

User checks

In addition to the competent person testing regime, staff should also check that equipment is free from an obvious defect before use.

Staff do not have to be qualified electrician to undertake a visual check of electrical equipment. If there is any doubt, the equipment should not be used until it has been checked and declared safe by a competent person.

Examples of defects to look for would be the charring of or discoloured leads and plugs, frayed leads, broken plugs, missing equipment covers and any other damage to the equipment itself.

Any faults MUST be reported to the management and the equipment affected must be removed from use immediately.

Portable Appliance Testing (PAT)

Staff testing portable electrical equipment must have been trained to do this on a recognised “Portable Appliance Testing (PAT) Course” or be able to demonstrate competence through knowledge, training and experience.

The HSE guidance specifies that only three types of test need be undertaken. These tests are:

Visual

Visual

- Check the length of leads to ensure it is correct for the appliance

- Check leads for damage

- Check for plug damage

- Check that plugs are fitted correctly

- Check that the appliance has the correct fuse rating

- Check that wires are correctly connected

- Check all extension leads (note that leads are treated as a portable appliance in their own right) and therefore should be checked for the above points where relevant

Earth bond

- Test that the bond is fitted correctly (i.e. from plug to appliance chassis)

Insulation resistance

- Visually check for deterioration of the insulation

- On testing, any leakage of the current to earth fails the appliance

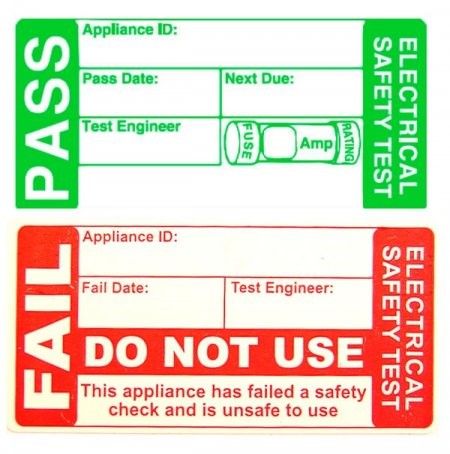

Maintaining PAT Records

Although the Electricity at Work Regulations 1989 does not require the production of testing records, the National Ice Centre considers that this information is essential and must be maintained at all premises.

This general requirement also extends to premises where we only have communal areas although in certain cases, it may not feasible to retain this information on site and where this is the case, other arrangements must be made and the location of this information must be identified.

Frequency of testing

Frequency of testing

A common misconception is that PAT testing needs to be undertaken annually.

Although considered as good practice that all electrical equipment is tested on an annual basis, managers should consider the consider the appropriate re-test frequency for equipment within a formal risk assessment and should consider:

- Equipment use

- Type

- How often it is moved

- The environment it is in

- Potential for damage

- Whether the equipment is hand held

Managers should ensure that equipment which is moved often or used in harsh environments such as cold rooms or where damage is likely to occur must be tested at least annually.

Equipment moved infrequently and used in normal office situations may only need to be tested every 3 to 5 years.

Certain equipment containing sensitive electronic components (e.g. computers) can be damaged by appliance testing and expert advice should be sought.

New equipment does not require testing however this equipment must be put onto the register and included on the next scheduled test.

For this to apply, proof of purchase must be retained and kept with the electrical register until it has been formally tested.

To assist managers, a Portable Appliance Test (PAT) asset Register form is available to record all equipment that requires testing.

Competent Person

The definition of a competent person given in the Electricity at Work Regulations 1989 is as follows:

“A person in the possession of sufficient technical knowledge or experience to be capable of ensuring that danger is prevented.”

The scope of technical knowledge or experience should include:

- adequate knowledge of electricity

- adequate experience of electrical work

- adequate understanding of the system to be worked on and practical experience of that class of system

- understanding the hazards which may arise during the work and the precautions which need to be taken

- ability to recognise at all times whether it is safe for work to continue

The competent person will normally have a formal qualification.